Sheet-fed vs. Web Press: What’s the Difference?

Publishers and businesses rely on print manufacturers to deliver high-quality marketing materials and books in a timely manner at a reasonable price point. Many of those professionals take their expertise a step further by understanding what happens behind the scenes when an item is sent off to their printer. In this article, we’ll dive into a step of the printing process so you can make more strategic decisions about your printing – how paper is fed into a large printer.

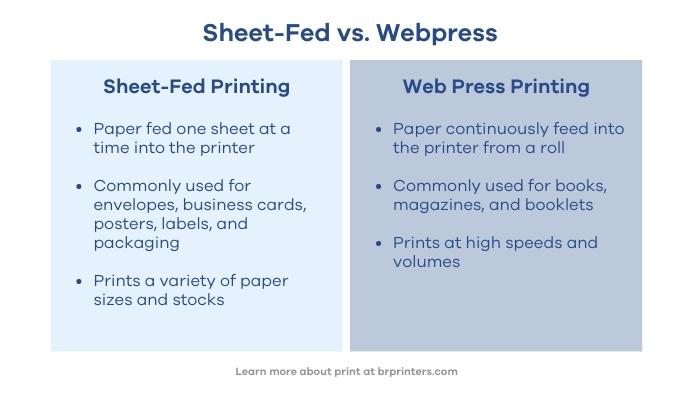

Have you ever seen large rolls of paper? That’s called web press printing. Another type of printer is a sheet-fed press where paper is fed into the press one sheet at a time. The printing process is constantly evolving, making faster, more affordable, and high-quality outputs. Web vs sheet-fed seems like a small piece in the printing process, but it can have a major impact on your printing job. Want to know how? To understand why this simple difference matters, you must understand the difference between the two printing processes.

What is web press printing?

When a roll of paper is continuously feeding into a press without being cut until the printing process is over, that’s web press printing. Web press printing requires large machinery that can often feed multiple rolls of paper at once and have reported up to speeds of 3,000 feet per minute. The speediness of this process makes printing tens of thousands of books a day possible therefore earning it great popularity among publishers.

How do web presses printer work? To simplify it, large rolls of paper are connected to the web fed press at the very beginning of the line and once the printing is complete, the roll of paper is then cut into sheets and sent off to post press.

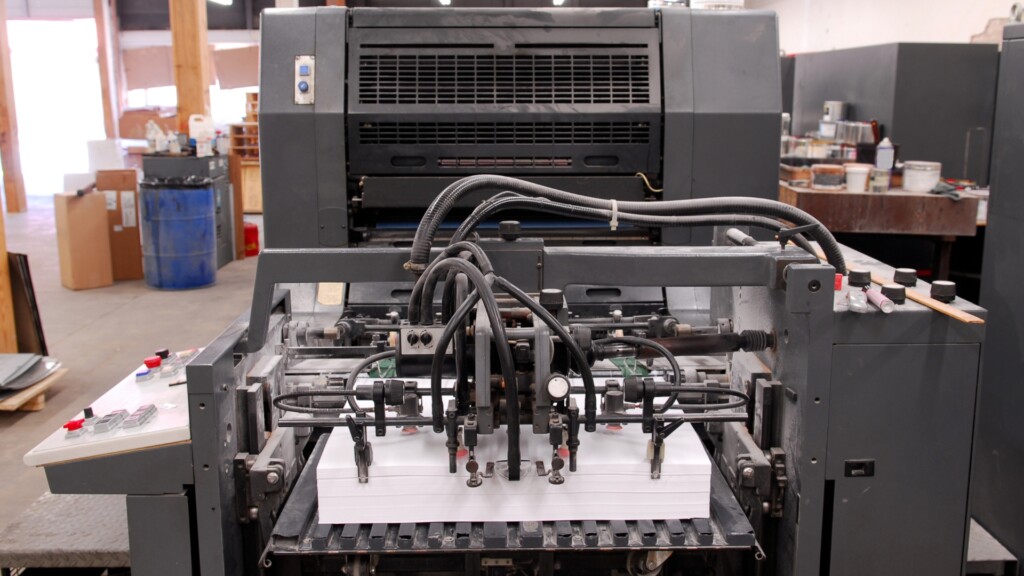

What is sheet-fed printing?

When paper is fed into the press one sheet at a time, that’s called sheet-fed printing. While feeding one sheet at a time into a printer sounds like a slow process, advanced technology and vacuum cups keep print speeds competitive and manual labor needs low. Sheet fed presses are known for the quality of print, customization, and size and stock flexibility. Many marketers and businesses might not know it, but they rely on sheet fed presses to produce their printed material such as direct mail and commercial print products like envelopes, business cards, posters, labels, and packaging.

What’s the difference between sheet-fed press and web press printing?

The difference is this: when paper enters the printer on a large roll, it’s web printing and when individual sheets of paper enter the printer in a stack of sheets, it’s sheet-fed. How the paper enters the machine determines whether it’s sheet-fed or web-fed.

A follow-up question for publishers, marketers and businesses interested in large print projects is, why does this difference matter? It matters because the printing method used to print your products and materials can impact the price, speed, and quality of your project. Web presses are popular for longer-run projects with no customization and variable data requirements. Sheet-fed presses are an amazing option for a shorter run with variable data and can offer more paper stock and substrate sizes. Unlike web press printing, for sheet-fed printing, the rolls of paper are cut before they enter the printing press. Purchasing pre-cut rolls of paper or cutting paper before feeding it into the printer does come at a cost. When discussing costs, there isn’t a clear choice because it’s all dependent on your project’s needs, market shifts, and what your printing company can offer you.

A Printer with Endless Capabilities

Based in San Jose, CA, with facilities in San Diego, CA, Denver, CO, Appleton, WI, Cincinnati, OH, and Independence, KY, BR is a provider of book, commercial, and large format printing and marketing services, promotional products, value chain, and logistics management to marketers and the publishing industry’s most recognizable names. BR’s national footprint, combined with a solution-centric focus, allows it to leverage data and technology while maintaining an appreciation and respect for traditional print craftsmanship.

BR Printers is trusted by many of the nation’s largest education and trade publishers and businesses. When you partner with BR Printers, you’re receiving high-quality digital and offset printing and guidance from our industry experts. We are committed to putting our customer’s needs above all else. How can we help you? Contact BR Printers today.